Drilling From The JOIDES Resolution

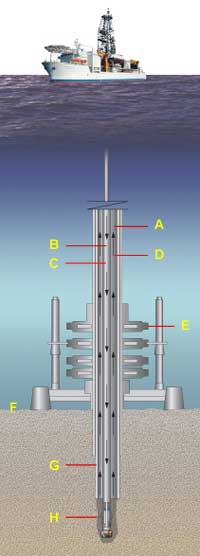

In a typical drilling operation, the first step is to pound a large piece of pipe into the sea floor. The pipe—called a riser or conductor casing—may be as large as nearly a meter (3.28 ft) in diameter. It is permanently attached to the sea floor and reaches almost to the drill floor beneath the derrick. Since the riser does not move from the sea floor, it serves as a reference to determine the depth. The actual drilling takes place inside the riser, which is also used to conduct the drilling mud (liquid used in the drilling process) as it returns to the surface. A safety device called a BOP (Blow-Out Preventer) is either mounted on the seafloor or attached to the top of the riser. The BOP is like a giant valve that the drillers can use to shut off the well if they run into unexpected pressure.

Riserless Drilling

Typical Drilling Operation

Image from Schlumberger Oilfield Glossary

|

Drilling from the JOIDES Resolution is not done in the usual way. It does not use a riser, nor does it use drilling mud. In a technique called riserless drilling, the drill bit is placed directly on the sea floor at the start of the drilling process. Ordinary seawater is used instead of drilling mud to lubricate and cool the bit, and to carry the cuttings—in this case only as far as the sea floor. However, without the riser, its equipment, and drilling mud, there is no way to control pressure. Therefore, it is important to avoid drilling into hydrocarbon deposits (natural gas, petroleum, etc.). If the drill accidentally enters an oil reservoir, oil would pour out of the hole and pollute the ocean. If it ran into natural gas, the gas could bubble up to the surface right under the drillship, risking an explosion.

Another potential disaster would be if the gas bubbles built up beneath the ship and reduced the density of the water. Eventually the water would no longer be able to support the ship, and the ship would suddenly sink! Because of these risks, in riserless drilling, special care is taken not to drill into any hydrocarbon deposits. Before and during drilling, the site is carefully analyzed to see if it is likely that such deposits might be in the area.

What does drilling mud do?Drilling mud is a chemical mixture with a consistency similar to ketchup. It serves several purposes in the drilling process:

|

The Drilling Process

Drilling aboard the JOIDES Resolution is done from the rig floor, a platform located in the center of the ship. Once the ship is in position at the site, drilling begins and continues 24 hours a day. The drill pipe is stored on a rack in 9.5 m (31 ft) lengths called long joints. The crew connects three long joints together at a time to make a stand. The drill bit is put in place, and a mechanical device called an iron roughneck connects stands together to make up the drill string. The crew lowers the drill string carefully down through the moon pool, a 7-meter (23 ft) wide opening that extends right through the bottom of the ship. The drill string is lowered until it reaches the sea floor. If the water is 5,500 m (18,045 ft) deep, the entire process would take about 12 hours.

A core is a column of rock and/or sediment taken from the center of the borehole during drilling. It will contain whatever solid or broken rock, conglomerates, sand, shale, clay is in the terrain being drilled. Ideally, the core would always come up in one piece, but this isn’t always the case.

|

Photo courtesy of IODP. The core catcher. |

|

Photo courtesy of IODP. A fresh sediment core sample is carried along the catwalk. |

|

Working on the drilling floor |

Photo courtesy of Natural History Museum, London. Even though the walls of the pipe are about 2 cm (0.75 in) thick, a stand of drill string can—and does—bend! |

When everything is in place to retrieve the core, a core barrel is placed inside the drill pipe and allowed to freefall until it lands just above the rotary core barrel (RCB) bit. The bit is designed to allow the core to pass through its center and into the core barrel during the drilling process. At the bottom end of the core barrel is a short connecting tube called a core catcher. The "teeth" in the core catcher allow material to enter the core barrel but prevent it from falling back out. The core barrel is lined with a plastic core liner to keep the core material intact.

When a 9.5 m (31.2 ft)—or less, if there are problems—section of hole has been drilled, the core barrel is brought back up to the ship. The plastic-wrapped core is removed, carried to the catwalk, and prepared for study in the laboratories.

During the drilling process, the bit may need to be changed—even several times, if the borehole is deep. Every time the bit is replaced, the entire drill string must be brought back up onto the ship. When the new bit is in place, the crew reassembles the drill string and directs it back down through the moon pool and into the borehole to continue drilling. Imagine how difficult it must be to guide the drill string back into the well from the water’s surface! To make it possible, a reentry cone is placed on the seafloor at the drilling site. With the help of the reentry cone, an underwater television camera and scanning sonar technology, the crew is able to put the drill string into the borehole easily.

|

left: Examining a core. right: A reentry cone waits in the moon pool area. Photos courtesy of IODP. |

|

Drilling Topics

|

Riserless Drilling The Drilling Process |

|

Heave Compensation Dynamic Positioning Wireline Logging |

|

Specialized Equipment Drilling in Extreme Environments Determining Accurate Depths |

This content has been re-published with permission from SEED. Copyright © 2026 Schlumberger Excellence in Education Development (SEED), Inc.